Cable Manufacturing

Finding the optimum solution for your requirements profile through targeted individual consultation is a matter of course for us. Delivering quality in accordance with the “Made in Germany” seal of quality is equally important. In addition, we have many years of experience in cable manufacturing and licensed production processes audited by our partners.

Your reliable partner for cable manufacturing

We support you in the creation of your individual cable harness concept and work together with you on the technical documentation and the selection of components. With the determination of suitable manufacturing processes, our production manufactures your individual cable harnesses.

Furthermore, we accompany you through prototype and pilot series phases up to series production. Typical quantities required by our customers can range from 1 to 1000 pieces per year. Individually agreed lot sizes of 1 to 250 pieces per lot are requested throughout the year.

By means of our customer-specific cable manufacturing, the desired procurement costs as well as the qualitative requirements are met over the complete product life cycle.

Cost, delivery time and production

How much does the cable manufacturing cost?

A general statement, how much the cable manufacturing or especially your cable harness costs, is of course difficult to make without further information. For a quick price estimate on your request, do not hesitate to contact us at any time. If necessary, we can provide you with your price within 2 to 3 days.

The costs of an assembled cable are basically composed by the parts of material, production time and set-up costs. The following list shows the fundamental starting factors regarding pricing. These are decisive for all further considerations.

- Number of pieces

- Complexity

- Component selection

By far the most important factor is the number of pieces to be produced. This has an influence on the economically viable procurement and manufacturing process. Whether it is one or a few prototypes, a small series or a large series is therefore of great importance. Often cable manufacturers are specialized in one or the other series area. For this reason, it can make sense, especially in the case of planned large series, to order the prototype phase and small series from a different cable manufacturer than the large series.

In general, the various items in the price calculation are weighted differently depending on the number of units. As the number of units increases, the share of necessary machine and system set-up costs decreases. On the other hand, the savings in production time increase in comparison to manual production. In addition, the material share often decreases exponentially. Due to the potential savings in material costs, it is advisable to establish a standard in the selection of components.

The economically viable level of automation in cable manufacturing currently ends with assembly on lay-up boards. Even today, this work step is still done manually. For this reason, complex cable harnesses are manufactured in very high numbers and volumes in Southern and Eastern Europe, Asia and North Africa. One example of this is the wiring systems installed in passenger cars. Due to the enormously high quantities of integrated procurement, the savings outweigh the use of resources and the logistical effort involved in procurement.

One possibility for further indirect price reduction, for example, is to add value to the service. This solution is already highly valued by many of our partners. In addition, there are other effective options to reduce costs in the case of longer cooperation.

We are specialized in prototypes and small series. Simplified, the cable manufacturing in Germany has proven itself with these quantities:

- Simple cable harnesses: 1 to 1000 pieces/year

- Complex cable harnesses with laying board: 1 to 500 pieces/year

The individual batch sizes requested are agreed on a case-by-case basis. These typically range from 5 to 250 pieces/lot.

In conclusion, the optimal interplay of price, quality and flexibility for the customer must be found in cable manufacturing! A one-sided consideration and weighting of one of the three parameters increases the risk of subsequent disproportionate expenses.

What is the delivery time for cable manufacturing?

Typical delivery times in cable manufacturing varies depending on the complexity between:

- 1 to 2 weeks for simple cable harnesses

- 3 to 4 weeks for complex cable harnesses

The delivery time is made up of the material procurement time and the production time. The time required for material procurement and production can often be significantly reduced through targeted measures. Experience shows that it is not uncommon for only one or two factors to be decisive for a longer delivery time.

Particularly in the case of recurring orders, blanket orders, for example, are an ideal way of guaranteeing the desired delivery time and at the same time security of supply. In addition to classic framework agreements, there are also other conceivable ways to profit from synergies in your own portfolio.

Why is design important in cable manufacturing?

Assembled cables have become a major part of the functionality of many vehicles and systems today. With the increasing trend towards electrification and expansion of electronic options, the complexity must inevitably increase further. Thus, professional design in cable assembly is becoming increasingly relevant, as has already happened with many product groups. In addition to pure clarity, the design view of assembled cables offers great potential. Depending on the industry, these can be

- Reduction of the number of variants – Reduction of production costs

- Reduction of weight

- Increase in assembly capability – Reduction in assembly times / increase in throughput

- Reduction of failure probability – Reduction of costs in after sales / complaints

- Optimization of components – Saving of resources

- Outsourcing

- …

Unfortunately, the potentials, especially for very small and small series (5 to 400 pieces), are still used far too seldom in wire harness production. A construction with the help of CAD-supported programs and the utilization of the data gained from it, is worthwhile in most cases.

However, the acquisition of such a program, the data collection, evaluation and implementation in the own production is connected with high internal expenditure.

For this reason, we support our partners here with our know-how and the structures we have already established.

In the past, we have been able to work together with many of our partners from the automotive, mechanical engineering, vehicle construction and many other industries to develop their optimal concepts for cable manufacturing. The most important thing here is an individual approach.

How does the production of cable assembly look like at WMH Herion Linner?

In detail, there are minor deviations to the following production processes depending on the type of cooperation with the customers. The reasons for this can be found in customer-specific agreements, as already described in the topic of delivery time. In the basic structure, however, cable assembly works in a similar way. The following production steps are not bound to the mentioned sequence. Depending on requirements, the sequence can be changed, supplemented or parallelized.

Organization and work preparation

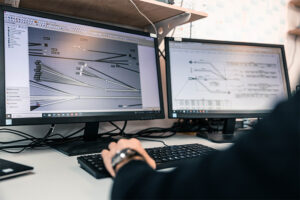

In the first step, it is necessary to prepare a scheduled work plan. This is based on the specifications agreed in the quotation phase. With the help of our work plan modules, it is possible to create a schedule that is as flexible and standardized as possible. After drawing the wiring harness once in the CAD software EPLAN, all documents necessary for production, such as pinning plan, cutting lists and printing, can be generated automatically.

For the subsequent, smooth and effective production of assembled cables, the work preparation is already indispensable. In the list you will find typical work steps:

- Creation of work plan

- Creation and provision of production-relevant documents

- Ordering material / provisioning

- Pre-assembly of the required material / semi-ducts

- Production of assembly aids and test adapters

Production

Once the production order has been approved, all cables can be cut and printed fully automatically using the automatic cutting machine linked to EPLAN. A relatively high degree of automation offers significantly higher accuracy and reliable repeatability compared to manual cutting. In addition, production times and thus prices per piece can be reduced. Unfortunately, there is no manual alternative for line printing. Especially for pinning and later after sales spare parts assembly, line printing is a great labor saver.

Depending on the number of pieces, the pre-cut wires are crimped with a semi-automatic crimping machine or manually with crimping tools. Only with the use of automatic crimping machines it is possible to guarantee demonstrably higher quality crimp connections. For this purpose, crimp force monitoring is used.

Typical measurements that are performed are pull-off tests as well as micrograph analyses. Economically, semi-automatic or fully automatic crimping becomes interesting when machine costs as well as set-up costs are recovered through savings in production time.

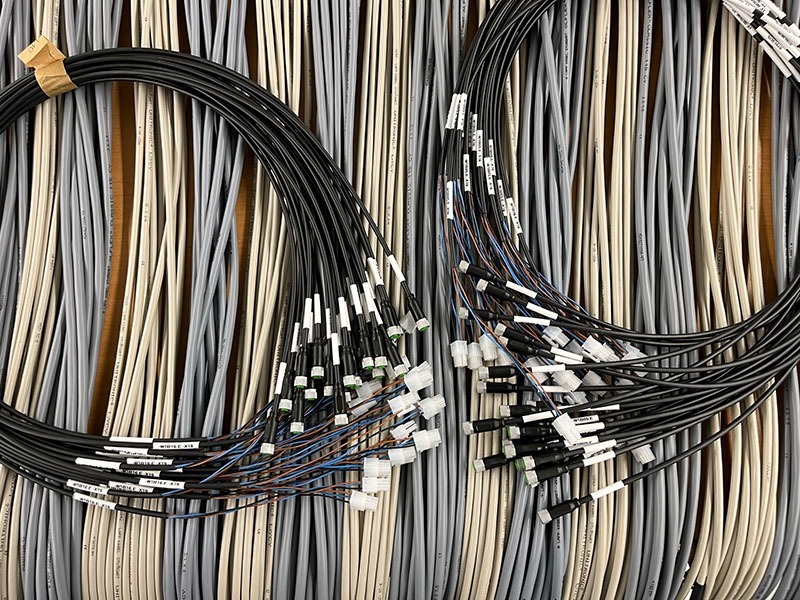

In the next step, the assembled cables are mounted. For more complex cables, assembly aids provided by the work preparation department are used. Typically, these are cable boards and cable screens. Cable plans for placement can also be generated using the CAD software.

After placing and assembling the plugs and connectors, the finished cables are put on the test bench. Here again, the number of pieces and complexity play an important role. Accordingly, the 100% test can be performed manually or fully automatically. With a test adapter and test program, the electrical test is performed and documented easily.

Manual work or machine work? What degree of automation is required for cable manufacturing?

As already discussed in the sections “How does the production of cable assembly production look like at WMH Herion Linner?” and “How much does cable manufacturing cost?“, the decisive factor is economic efficiency.

The core statement there is the higher the number of pieces and thus the potential savings in working time versus setup costs, the more interesting a higher degree of automation becomes.

However, there are also exceptional cases. Especially in prototyping, testing / validation of series and laboratories, only small quantities are required, which must correspond to the series in terms of quality or are generally subject to very high requirements due to the applications. In these cases, a semi / or fully automated solution is still used.

An own setup of the machinery for the automated production of assembled cables is relatively uncommon and of course requires an individual consideration. A later section will discuss when outsourcing is a worthwhile option.

At what timing should I start contacting a cable manufacturer?

That depends entirely on the type of collaboration you want and your level of cable assembly. But in general, it is not a disadvantage to bring a potential partner on board at an early stage.

Many of our customers already appreciate the offer of a supporting activity during the development and prototype phase. In the case of existing cables and cable harnesses, subsequent optimization is also possible.

The first step is to contact us. Here you can reach us at any time by phone or e-mail.

What is the cooperation process like?

After initiating contact, an appointment is made with the aim of getting to know each other. The ideas of the future cooperation will be discussed in more detail.

This is followed by an initial sample inquiry. This serves to determine the quality and work processes. Depending on the customer, the auditing and validation of the new supplier can of course vary.

After the validation has been passed, the first regular order is placed.

Experience shows that the successful cooperation will be extended piece by piece.

As a system supplier, we offer several other product groups within and outside of electronics. It is not uncommon for the cooperation to grow beyond cable manufacturing

Quality characteristics of a good cable manufacturing

What are the quality characteristics of cable manufacturing?

At first glance, qualitative defects are difficult to detect. However, a closer look quickly reveals how well a cable manufacturer produces its cable harnesses. Basically, the quality characteristics differ according to the planned application. Therefore, it is advisable to clarify the necessary quality requirements at an early stage. With the following clues, you can form your own quality assessment of the cable harness and the suitability of the manufacturer:

Cable harness wiring and cabling

One of the essential features is the wiring. It is important that the wiring of the cables corresponds to the cable plan in order to be able to guarantee the functionality appropriately. We recommend a 100% automatic control. For this we check our production by using a test system with a mating connector set. Of course, you will receive a consolidated report of the measurements for each lot.

Crimp and solder joints

Cable harnesses sometimes consist of very complex connections. To ensure a reliable connection, the quality of the crimp and solder joints is crucial. Defined crimping forces are specified by the manufacturer for each crimp contact. We achieve this level by using only original tools. In addition, the crimping forces are monitored and controlled by pull-off force testing.

Labeling according to cable plan

To avoid mix-ups during cable assembly and after sales, correct labeling is crucial. This should be standardized and easy to read. It is also important to provide it in the correct language. In addition to standardizing our labeling process, we also use a wipe test to check this quality feature. In addition, production times can be reduced in cable manufacturing.

Traceability

Traceability is another quality feature that can be used to assess the quality of the cable manufacturing process. In our company, the traceability of each cable is solved by a unique reference number. This contains all the information about the tools with which the cable harness was manufactured.

Comprehensible documentation

You can check the trustworthiness of a cable manufacturer by means of proper and standardized documentation. This should contain all relevant parameters and be comprehensible. We have created a CAD supported standard with the software EPLAN Harness.

Cable sheath and conductor cross-section in climatic conditions

The cable sheathing as well as the intended cross-section must meet the environmental requirements. Unsure of the prevailing climatic influences in your application? We will of course be happy to help you analyze the relevant environmental conditions.

What quality do my inquiry documents need?

We are regularly confronted with the situation of “currently insufficient inquiry documents for the cables”. Of course, it is an advantage if a technical drawing, parts list, etc. are available. However, their preparation involves a relatively high internal effort.

Some of our customers happen to be

- at the beginning of the outsourcing of cable assembly

- at the beginning of professionalization of cable harnesses

- in the middle of the development phase of a new product/project.

In such cases, the resources to prepare the documentation could not be invested yet. That is why we have defined for ourselves the WMH Herion Linner standard. When using it, the “status” of the documents is secondary at the beginning. A cooperation can already be started with concept drawings, sketches or a prototype cable harness. If required, we can also provide you with the documents created with the help of a CAD program.

What are the typical errors in cable manufacturing?

One of the primary mistakes can be differentiating the product’s wiring harness or individual cables. However, this section focuses exclusively on “technical and qualitative errors”.

The most frequently occurring errors in the cable harness production are:

- Wrong dimensioning of the cables

- Wrong tool

- Differences between assembled cables and documentation

- Not maintained documentation of revisions

The correction of errors on the finished cable, in the worst case already in the application, are often disproportionately costly. For this reason, it is of particular importance to ensure the required quality with proactive measures and thus minimize the potential for errors.

For the correct dimensioning of cables, the first step is to know the environmental surroundings and thus the exact requirements. Based on this, cross-sections, sheathing, protective measures, etc. can be derived. Therefore, no savings should be made at this point of cable assembly.

The use of the appropriate tool serves several purposes. Even before the actual production, the use of the right CAD software significantly reduces the potential for errors. By using software, colliding components and discrepancies can already be identified. Furthermore, many potential, mental errors are eliminated. An example of this would be the automatic calculation of additional lengths due to bending radii.

Planning alone is not enough to produce a high-quality assembled cable. Thus, it is equally important to use the right aids and tools for the respective degree of automation during production. One possible solution is a managed tool database. The database contains, for example, original pliers and crimp applicators for the corresponding contacts.

The use of aids is particularly useful for production steps that are difficult to automate. For the laying of assembled cables, the construction of laying boards or cable sieves has proven its worth.

Deviations of the finished cable from the corresponding documentation should be noticed before leaving the factory. The best option for us at Linner is the automated 100% testing of cables. In such a test, each cable is tested via a test station before shipment. After the test adapter and the test program have been created once, the test is completed easily.

With the delivery of the cable harnesses, our customers naturally receive the corresponding test protocols for the respective batch.

Cable Harness - Definition

Cable manufacturing - What's that?

The term “cable” is used to describe both individual wires and their interconnections. The term “cable assembly” originates from the French and means “manufacture or production“. By definition, cable manufacturing or cable assembly therefore means the production of ready-to-connect individual conductors or the individual conductor composite. Since the pure definition is difficult to grasp, in practice the understanding often differs greatly with regard to the degree of complexity. The range extends from the production of a few bundled individual wires with connectors to entire cable harnesses and wiring systems.

Wiring harness production, cable, wiring harness and wiring system - terms and their differences

In the previous section, the terms cable harness production or cable manufacturing and cable have been explained in more detail. While cable harnessing describes pure manufacturing, the product can be further differentiated based on the degree of complexity.

Cable

As already mentioned in the question “Cable manufacturing – what’s that?“, a cable is understood to be the individual wires or the single-wire composite.

Cable harness

When several assembled cables are bundled to form a tree structure, the term cable harness is used. The options for bundling vary depending on the intended use. Classic solutions are the use of tape, cable ties and hoses. The types of cables used in the cable harness and what needs to be taken into account are discussed in more detail in the next section.

For the transmission of electrical energy and information, assembled cables as well as cable harnesses represent a cost-effective solution. For this reason, they are used in almost all industries. These include industries such as automotive, mechanical engineering, vehicle construction and many more. In addition to the pure economic benefits, cable harnesses offer many other advantages:

Before enumerating them, it remains to be mentioned that the actual product and their potential advantages are best realized in combination with an optimal manufacturing process within the framework of a customer-specific concept!

- Space saving

- Reduction of assembly times

- Additional protection against environmental influences and interferences

- Standardization (improved cost efficiency, reduction of error potential)

Electrical system

The term ” electrical system” is used when additional electronic components are added to the wiring harness. One of the larger fields of application is found in the automotive industry. In this case, the entire electronic system of the vehicle is understood as an electrical system. However, electrical systems are also used in many other products, such as municipal/construction/airport and rail vehicles. Here, the electrical system takes over the task of supplying power as well as the flow of information.

The elements used in an electrical system in addition to the wiring harness can be:

- Sensors

- Control units

- Display elements (displays, lighting systems)

- Actuators (electric motors)

- Bus systems

- Energy storage (batteries, accumulators)

What types of cables are there in cable assembly and what are their applications?

Especially in the mechanical engineering, automotive, plant engineering and vehicle construction industries are common cable types in cable assembly:

- PUR cables for extreme stresses

- PVC cables for medium stress

- RADOX cables for good oil and lubricant resistance, fire protection

- …

There are many other types of cables on the market. Each of them has its own special application. The reason for this is the environmental conditions, which are often very different in practice. Some of the stress types that can occur are:

- Mechanical stress: bending, grinding

- Electrical stress: voltage, current

- Thermal stress: temperature profile of the near environment

- Chemical stress: water, oil, other chemicals and liquids

Before starting the cable assembly, it is necessary to determine the combination of stresses and to select the right cable types.

Another decision criterion is the type of information to be transported. Will the cable be used purely for carrying voltage or will it be used to transport data. In the case of so-called data cables, protection against electrostatic and electromagnetic interference plays an important role. Two possible protective measures are twisting the cables as well as a protective shield in the sheath of the cable. Examples of such cables are:

- Ethernet cable

- Coaxial cables

- Bus cables

Manufacturers of such cables are:

In the production of assembled cables, we will gladly take over the selection as well as procurement for you. Due to the very different availability and procurement prices, we recommend to consider the expediency from the beginning of the development.

What are the connectors in cable manufacturing and what are their applications?

In their basic function, connectors in wire harness production fulfill the task of providing electrically conductive contact for the connection of two devices. Due to the very versatile requirements for the electrical connection, a number of different connectors have become established on the market. The manufacturer TE Connectivity offers more than 240,000 different variants in its portfolio. For a first rough overview, connectors can be classified into the following types.

- Data connectors

- Network connectors

- Graphics/video connectors

- AV connectors

- Low-voltage connectors

- PC internal connectors

For significant simplification, branch-specific applications have typically become established in cable manufacturing.

Under which circumstances is it worthwhile to outsource cable manufacturing?

Generally, the common principles of outsourcing apply to the outsourcing of cable assembly. Obviously, the advantages for the own company have to be considered individually. Nevertheless, advantages arise regardless of the industry, which lead to a short- / long-term increase in quality as well as improvement of the strategic market position of the company:

- Targeted concentration on their core business

- Reduction of costs

- Savings in infrastructure

- Quicker development of competencies

- More flexibility

At first, the question arises to what extent the limited resources of one’s own company should be allocated to cable manufacturing.

With a partner in cable manufacturing, you have more resources for strengthening your own core competencies while reducing costs at the same time. In addition, competences of specialists can be purchased quite quickly. This topic-specific know-how often represents a competitive advantage compared to the competitors.

Building up one’s own competence and production structure would be both lengthy and expensive. Therefore, the decision should be made at the beginning whether the activity of cable assembly is one of the company’s own core competencies or should be one in the future.

With the decision for a partner, it is usually possible to react much more flexibly to unforeseen or unpredictable tasks. Since recurring and often capacity-binding tasks are outsourced, more resources remain to react to these circumstances.

What should be considered in the supplier selection of a suitable cable assembler?

When selecting a strategic partner in cable assembly, there are several points to consider. However, the whole selection process starts with the search for suitable candidates.

As already briefly covered in “How much does cable manufacturing cost?“, many cable assemblers are specialized in certain quantities. If the requirement is based solely on quantities, you can use the previous section to make a preliminary selection of suppliers and the manufacturing location.

If you have already made a shortlist, you will find a brief overview in “What are the quality characteristics of cable manufacturing?” to get an idea of how good the quality of the sample cables tends to be, either alongside or in conjunction with your internal validation process.

What is there to consider when professionalizing cable assembly?

The motivation from which a professionalization of cable assembly is approached can naturally vary. Thus, it is of particular importance to adapt concepts of cable assembly to the desired goal. The potentials and goals are not always known from the beginning. Defining the concerns / backgrounds into goals should always be the first step. Here, as well, you can already count on our support.

Typical causes are listed as an example:

- Production volume has reached a certain level

- Complications or, in the worst case, delivery delays due to accumulation of errors in cable assembly

- Examination of outsourcing potential

- Optimization of assembly times

- Increased work preparation in the assembly line

- …

A general step-by-step guide rarely leads to the optimal result. The requirements are too individual for this. However, a lot can already be achieved with a project management approach.

After goals have been defined based on the demands and potentials, the recording of the current state is an important step. Which data should be recorded at this point can be found, for example, in the section “Why is design important in cable manufacturing?“.

Without knowing more about your company, it is very difficult for us to recommend further measures with a clear conscience. Based on this, we have listed a number of possible optimizing measures in no particular order or recommendation.

- General clustering (120% solution etc.)

- Increase complexity (mechatronic assemblies)

- Optimize components and production

- Optimization of purchase prices

- Optimization of processes around the actual product