Special Tools

We live precision and also pass this on to our customers via our special tools.

Find your perfect special tool

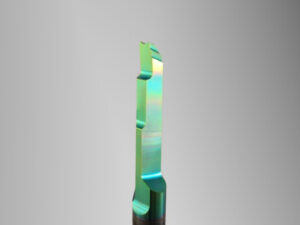

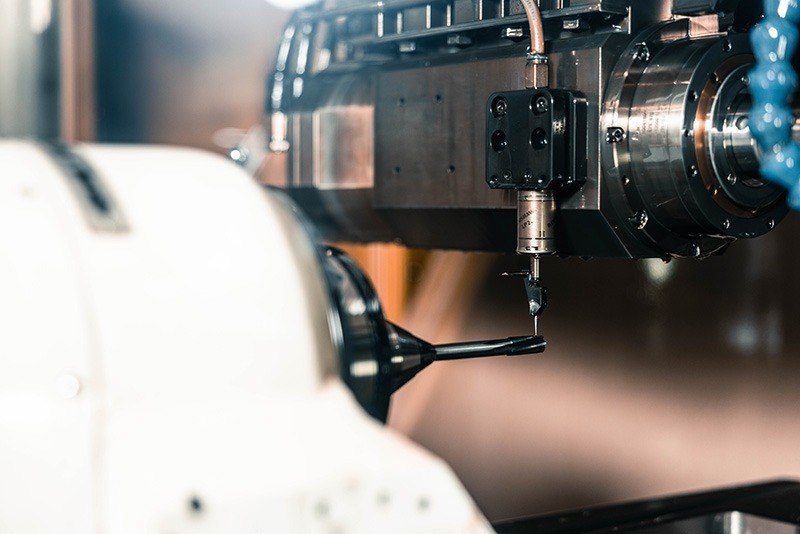

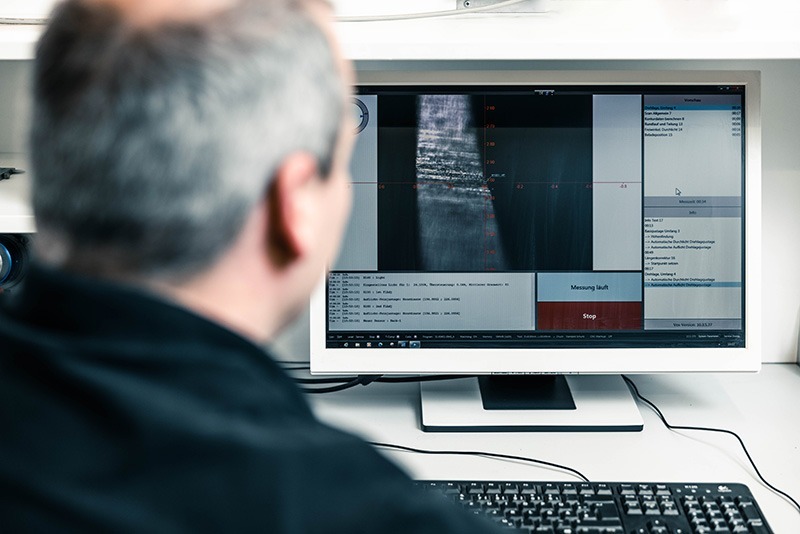

In addition to our sharpening service, we also offer you the production of new special tools. Our core competence focuses on the reproducibility of our processes, so that you always receive the tool that is optimized exactly for your application on a 1:1 basis. Our special tools are characterized by their longevity. As a result, you benefit from longer tool life with our tools, which leads to increased, economical machining in your company.

Insight into our services: Precision tools and special tools

In this section you will find an excerpt of our special tools. Did not find what you were looking for? Contact us and we will advise you on your project.

Good to know: milling tools and drills

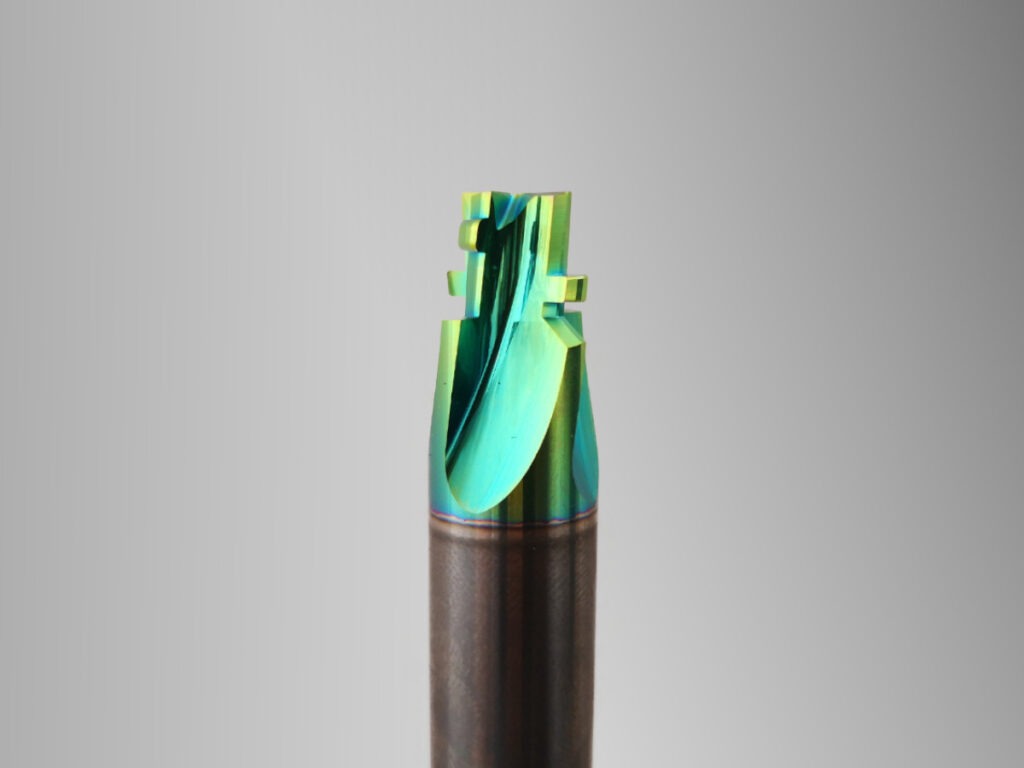

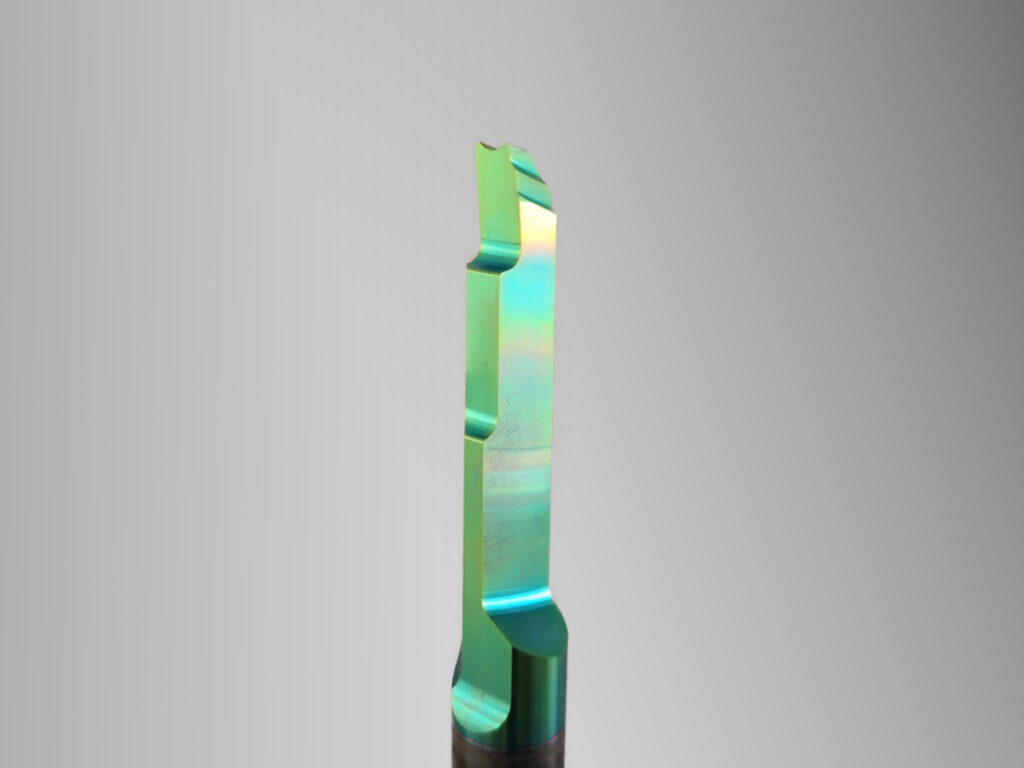

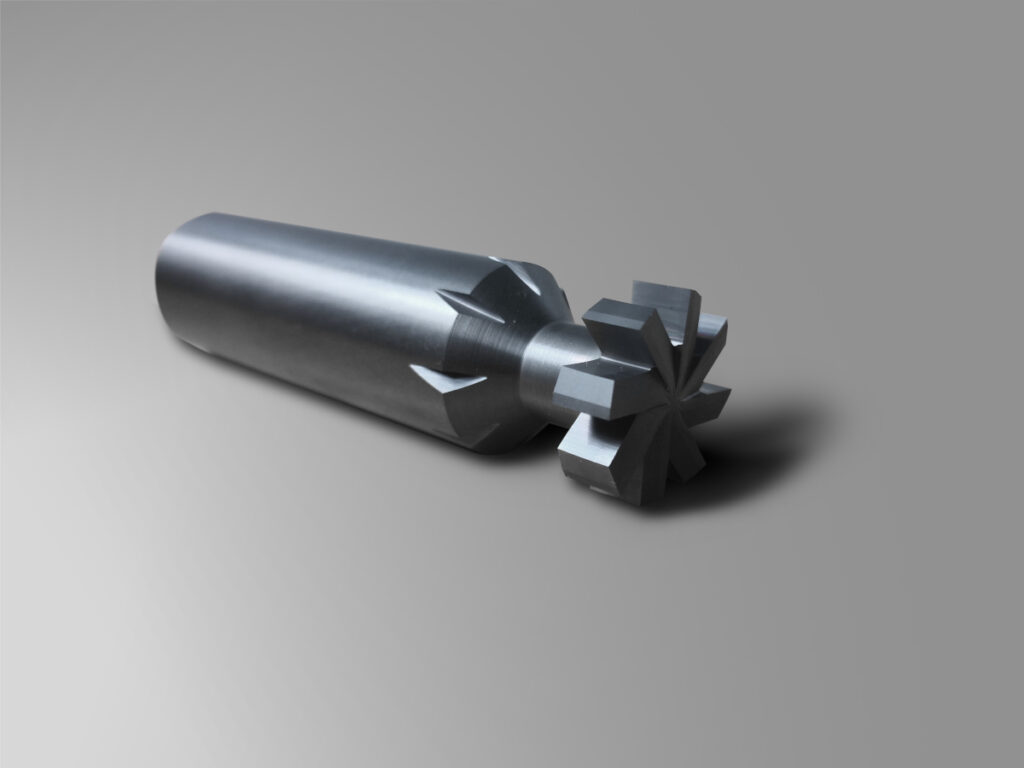

Milling is a machining production process in which material is removed from a blank in the form of chips. Milling tools are used for milling, which enable the machining of a blank both perpendicularly and obliquely to the axis of rotation. By adjusting the cutting edges, clearance angles and other tool parameters, different tool properties can be made possible that are suitable for the particular application. For example, conical milling tools can be used to ensure that deep cavities can be milled more effectively. Other cutter shapes, such as a dovetail cutter, make it possible to mill a dovetail-shaped groove.

Using a cutter that matches the workpiece has a positive effect on tool life and machine uptime. Let our team advise you! In addition to standard cutters, we also offer a wide range of special cutters.

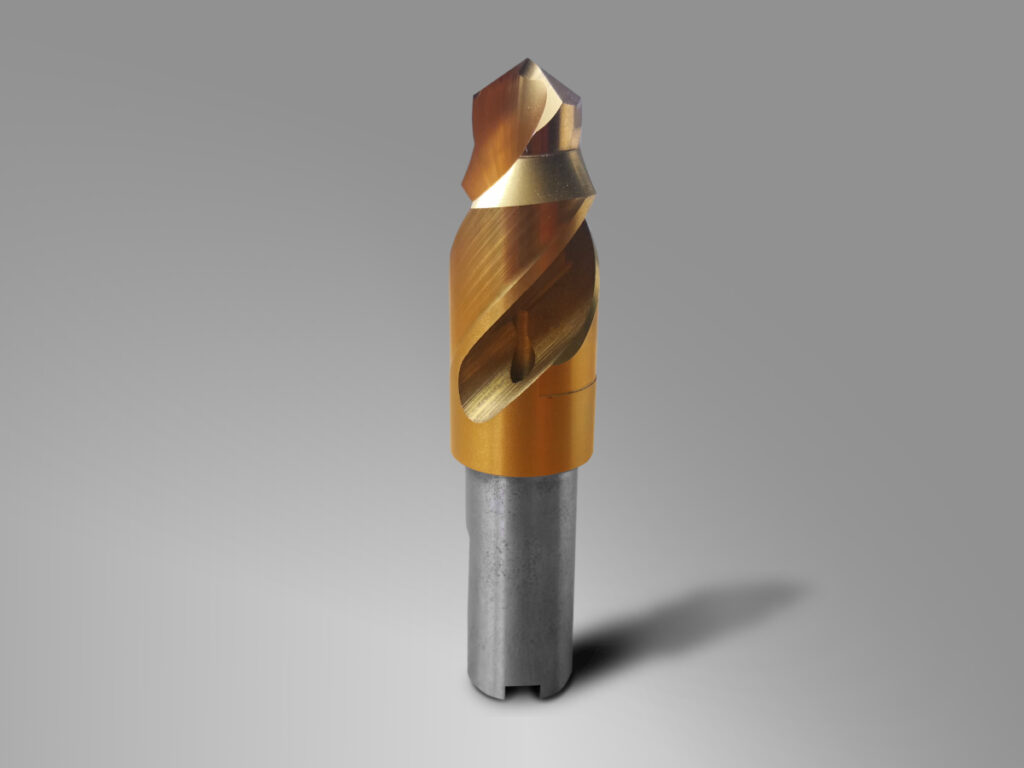

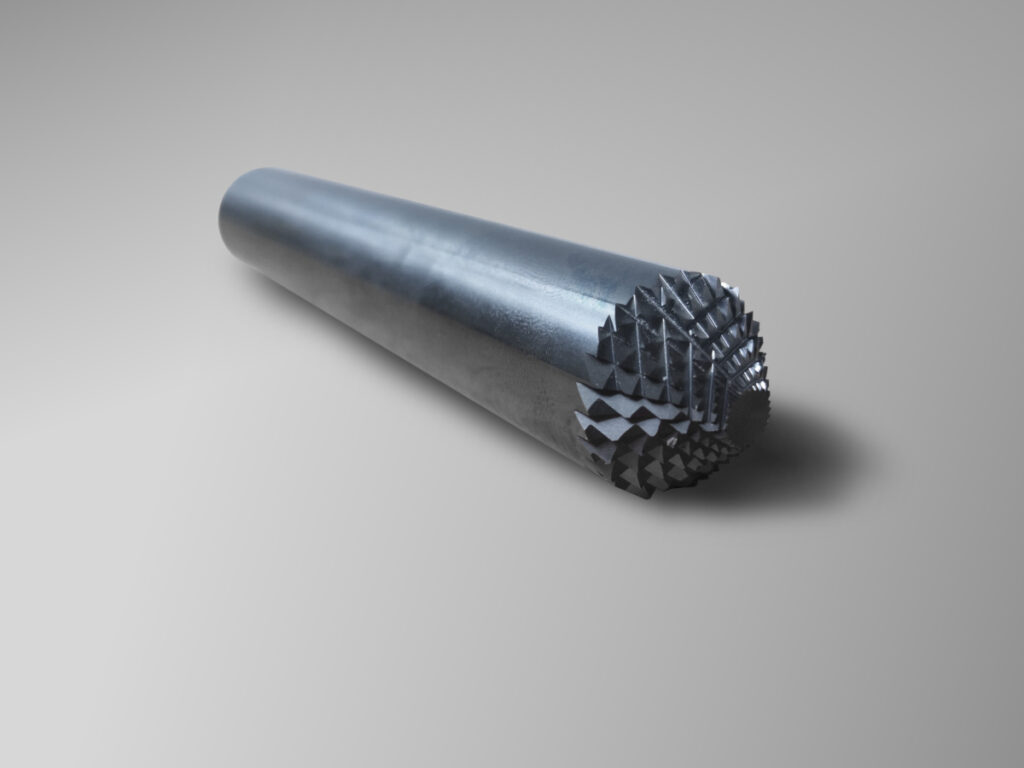

Drilling tools are used to drill holes. Their geometric nature is designed to convey the chips produced in the drill hole out of the cavity. The most common type of drill is the spiral drill. Special tool geometries can also simplify the machining process for boring tools. For example, profiled holes can be made in one pass with a special drill.