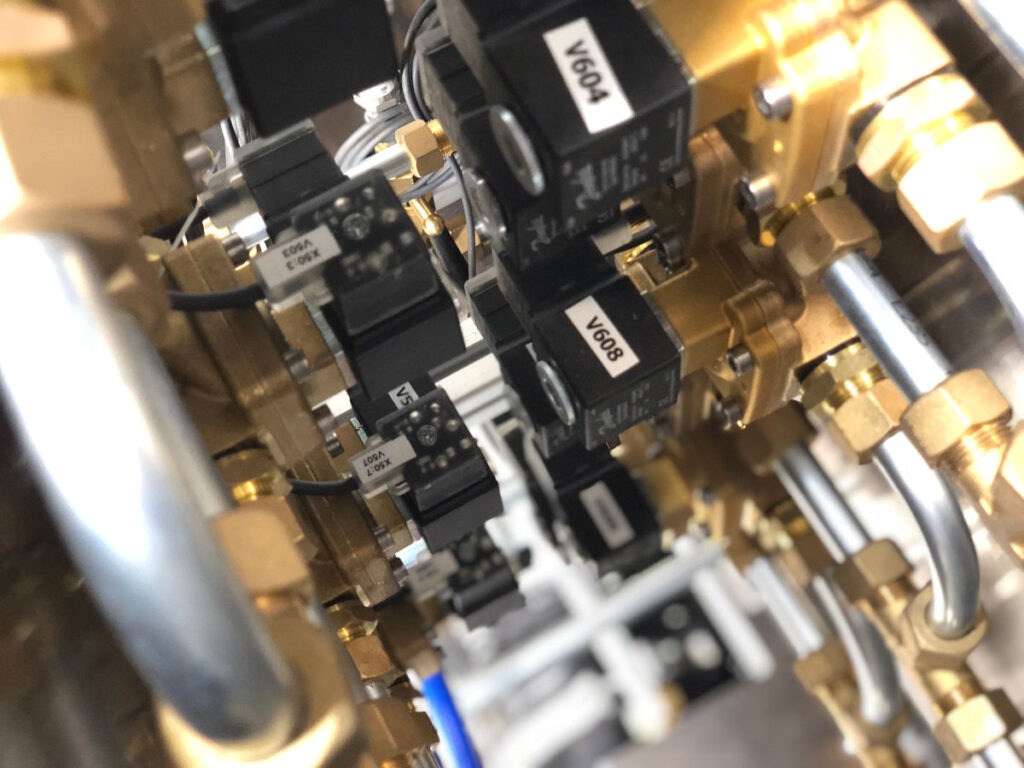

Valve Test Bench

Test the robustness of your products with our valve test bench in a pressure control range between 0-16 bar.

Your reliable partner for resilience testing

A valve is a mechanical, usually electrically controlled device that can be used to control the flow of a medium, e.g. air. To distinguish the valve from other shut-off mechanisms, a shut-off device is called a valve if the shutter is moved approximately in the direction of flow of the medium. The tightness and robustness of a valve’s closure capability can be tested using a valve test bench.

The test rig controls the valve to be tested according to a test profile, provides volumes and pressure, measures and stores data of pressure and flow. The valve test stand enables automatic detection of pressure, flow and leakage. Individual test profiles can be created and managed via our HMI (Human Machine Interface).

Our valve test bench convinces among other things by

- a very easy and uncomplicated setup: you can quickly compile your individual test sequences in a script and start testing immediately.

- our on-site support during commissioning and setup of the test bench.

- the high sampling rate to be able to analyze even dynamic processes.

Valve Test Bench - FAQ's

What is a valve test bench used for?

Why do you need a valve test stand? For reasons of quality assurance. The higher the quality of the product, the more satisfied the customer. Because that means that the product delivers what it promises. But how can you make a promise? Exactly: By validating the product to see if it stands up to its intended use.

That’s why test phases should be introduced as early as possible to check whether the valve meets the requirements before it is installed in the application. For example, valves are already tested during development or for quality control at the end of production (EOL – end of line). The goal: to determine many critical conditions for the product in calculated frequencies within a very short time in order to be able to make a statement about the robustness along the life cycle.

The valve test bench provides the pneumatic prerequisites for this. In practice, another component is often required to simulate the desired environmental conditions. This can be, for example, a climatic test chamber (air or liquid), or a vibration test chamber…

What does a valve test bench do?

Air pressure can be applied to valves at the inlet and at the control line on the valve test bench. The pressure curves can be determined as far as possible in a sequence. Here, as far as possible means that the pressure curves run within physical limits. The user defines a sequence of states and a number of repetitions. The test bench automatically establishes the states, measuring and logging measured values such as pressure, flow, temperature, etc. The test engineer can monitor the process.

The test engineer can always observe the test process. Limit values can be defined, which lead to alarm signals. After the test, the data can then be viewed to study the behavior of the tested valve in detail.

What is the pressure control range of the valve test bench?

The pressure control range in this application is 0 – 16 bar. On request, we will also be happy to check the use of other pressure control ranges for you.

What types of valves can be tested?

For example, the following pneumatic valves can be tested:

- Check valves

- Pressure regulators/pressure limiters

- Relay valves

If you would like to test other valves, we will be happy to check the requirements for them for you.