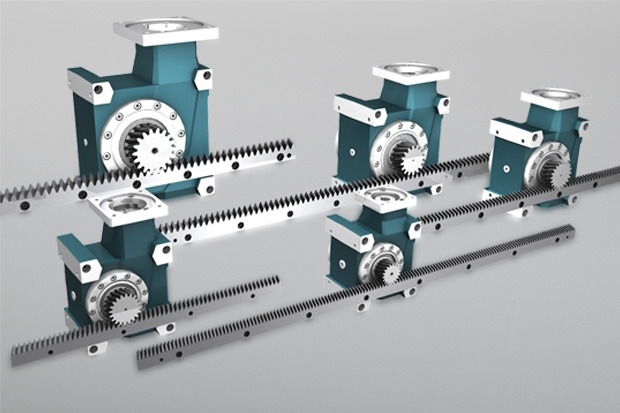

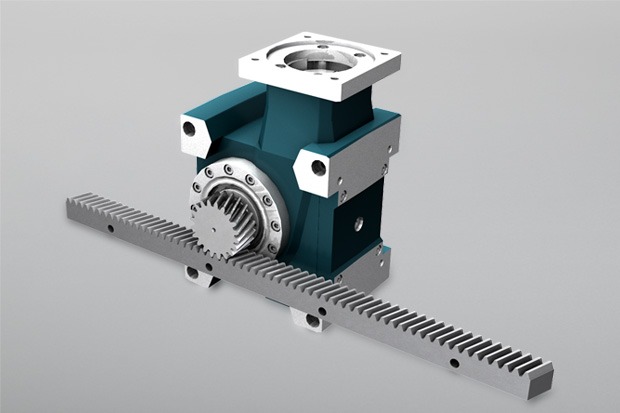

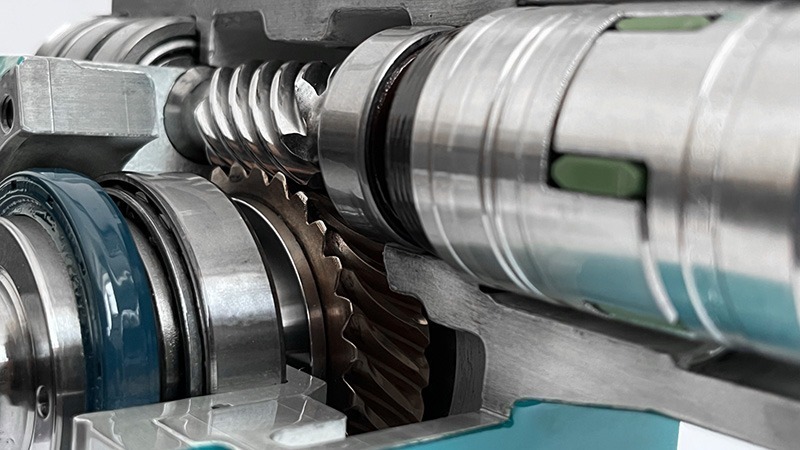

Servo Worm Gear Unit

Our servo worm gearboxes are impressive due to their perfectly matched components of gearbox, rack and pinion. We have over 60 possible versions, which allows you to put together a new kit quite flexibly. This means that you can easily scale your products and do not have to spend more effort than is necessary.

- Benefits

- Modular system

- Application Areas

- Variants

Convince yourself what benefits our servo worm gearbox offers you.

System Benefits

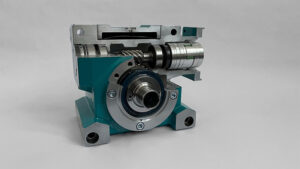

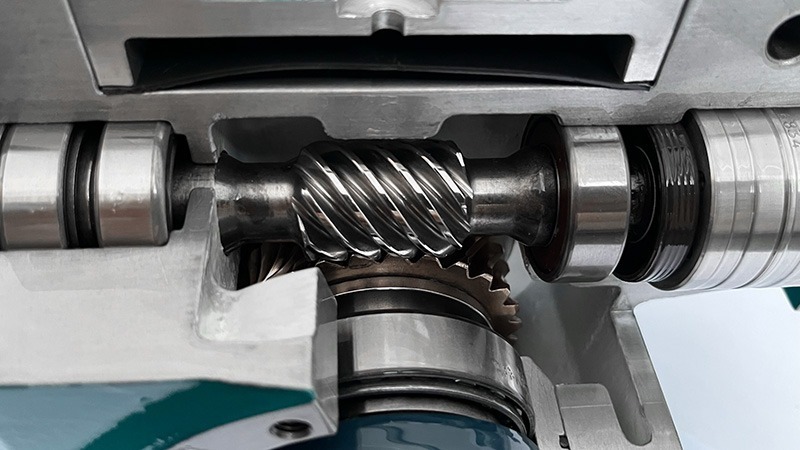

- very smooth running

- high wear resistance by using high-performance materials

- high energy efficient / high efficiency level

- suitable for all operating positions

- corrosion protection through stainless steel version or special coatings (optionally)

Rack & Pinion Benefits

- highest resilience through optimal choice of material and heat treatment

- high wear resistance through the use of high-performance materials

- very smooth running due to low manufacturing tolerances

- high overall efficiency level

- vibration and shock absorbing

Servo Gearbox Benefits

- high torsional rigidity

- vibration and shock absorbing

- corrosion protection through stainless steel version or special coatings (optionally)

- adjustable toothing backlash

- food grade oil with H1-authorization

Simple modular system – designed for easy combination

The variety of diverse drive elements is almost endless. Whether it may be Spur Gears, Pinions, Racks, Servo Gears or even something completely different – we have got you covered! Both the component version, as well as varying material properties obviously have a major impact on potential applications. But how to choose the correct components for your individual project?

Take advantage of our extensively modular system of our servo worm gear unit! All Pinion Shafts, Racks and Servo Gears are not only precisely matched to each other, but also available in a vast amount of different variations. This is a major advantage since it allows you to solely focus on given project requirements without having to worry about potential compatibility issues.

Do you already have a thorough understanding about operational requirements of your planned project? Great! You can simply go ahead and refer to the technical data sheets of our modular system. As mentioned before, all components are perfectly matched to each other and can easily be integrated into your concept.

In case you may not have specific information about operational requirements just yet, we will be happy to share our expertise with you. Together we will be able to find a suitable solution for your needs.

With our extensive portfolio, we enable ideal, high-performance solutions for a wide range of industries:

- Conveyor technology

- Intralogistics

- Packaging machines

- Handling systems

- Robotics & automation technology

- Health-Care & Pharma Industry

- Industrial & assembly machinery

- Machine tools

- Test engineering & process engineering

and many others

Our servo worm gear units are available in two variants:

Performance

- Reduced backlash

- Force-fittng shaft connection (shrink disk)

Eco

- Standard backlash

- Force-fitting shaft connection (keyway)

More information about the servo worm gear unit

We offer our servo worm gear units in 5 sizes: 040, 050, 063, 080 and 100. Further information on the respective technical specifications of our servo worm gear units can be found in our product brochure with technical data sheet.

Can’t find what you’re looking for? Contact us and we are happy to advise you on your project.

Accessories

Toothing components need to be maintained on a regular basis. Doing so, not only the availability of the product can be increased, but also the overall lifespan extended. Our automated maintenance options simply take over these processes – without any need of human interaction.

Having chosen the correct overall package, you can therefore easily lean back and relax on this particular topic. Our solutions range from different lubrication pinions, lubrication pumps to varying lubricants themselves. You will definitely be able to find the right components in order to meet your individual requirements.